How to Build Hardware & Cloud IoT Solution

For smart home product enthusiasts, there are several considerations for building a smart automation IoT solution.

Hardware Design

To start a IoT project, you would need to define the parameters & characteristics of the hardware, such as:

- Power consumption

- Portability

- Wireless range

- Battery life during operation & standby

- Ease of installation

- Data transmission rate

- Uplink & downlink capability

- Wireless frequency & reliability

- Security

- Compatibility with other protocols & device

- Cost & affordability

After deciding above factors, then you would need to find associated components & modules to perform each of the above function. An important aspect to consider is what specifications are needed. That is, are bare minimum requirement enough? Or do you want something that exceeds performance?

Every device on the market can have certain tradeoffs between functions. For instance, a smart water meter might require longer wireless range and low power consumption, while sacrificing data rate & successful reception. On the other hand, a wireless fire alarm system demands very accurate acknowledgement of wireless transmission, while consuming more power.

Building Prototype

Once you have the product hardware design in place, it is time to build the first working prototype. It is important to work with a manufacturer with experience in the fields and quality adherence. It is also important to begin writing codes that allow for wireless device communication. This part may be very time consuming as there will be multiples tests & bug that need to be addressed.

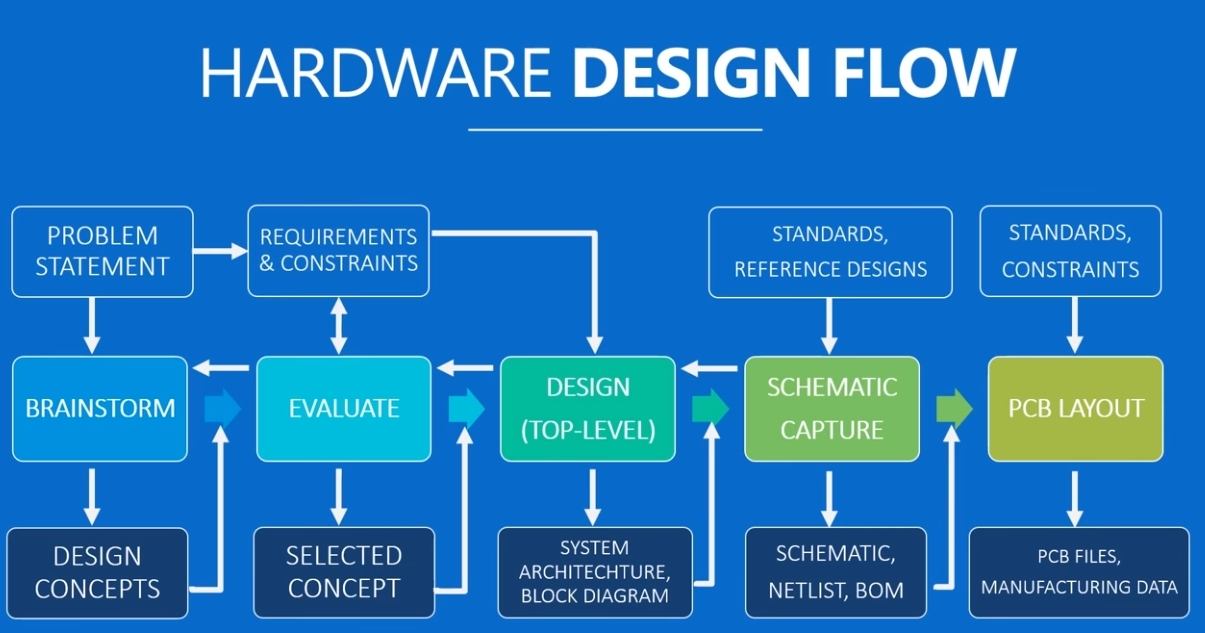

For rough hardware prototyping, a PCB will need to be designed using tools such as breadboard which allows for frequent circuit changes. Then, using an Electronic design automation software (EDA), you can draw the schematics & PCB layout accordingly. This process will help verify & validate the design for official production.

Physical Testing

Once the PCBA is complete, it can be assembled onto the hardware or exterior for physical testing. For advanced analysis, you may connect to existing cloud platforms for data storage & study.

Keep in mind that there is no perfect solution, but there is a solution that is best suited for your needs. For any inquiries or projects, please consult with one of our specialists for more information.